On-site Inspection

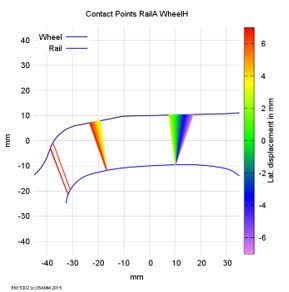

Perform site visits to inspect representative curve and tangent segments, collecting rail and wheel transverse profiles.

Additional Evaluation

Review track conditions, including geometry, friction, and switch conditions, to identify potential contributing factors to observed problems.

Addressing Critical Rail Treatment Issues

High costs associated with grinding/milling trains/trollies and track maintenance access.

High costs associated with grinding/milling trains/trollies and track maintenance access.

Concerns about grinding stone/milling cutter head consumption, fueling, and headcount.

Concerns about grinding stone/milling cutter head consumption, fueling, and headcount.

Risks of downtime, excessive metal removal, and fire control.

Risks of downtime, excessive metal removal, and fire control.

Compliance issues with grind plans and quality of executed work.

Compliance issues with grind plans and quality of executed work.

In the complex landscape of rail treatment, Global Rail Group understands the multifaceted challenges faced by railway companies.

Precision-Quality Assessments for Optimal Results

Global Rail Group offers comprehensive solutions to enhance rail treatment efficiency, including:

Assessment of compliance with grind plans and operational KPIs (GQI, PDI, PQI, EQI)

Assessment of compliance with grind plans and operational KPIs (GQI, PDI, PQI, EQI)

Evaluation of metal removal and asset selection/deployment (Mini-Prof: Before/After)

Evaluation of metal removal and asset selection/deployment (Mini-Prof: Before/After)

Selecting and deploying assets strategically, whether it's milling on-site, grinding, friction management or rail replacement.

Selecting and deploying assets strategically, whether it's milling on-site, grinding, friction management or rail replacement.

Improving operational efficiency by determining what areas to grind/mill and what to skip.

Improving operational efficiency by determining what areas to grind/mill and what to skip.

Guidance on machine/trolley sizing and OEM/contractor compliance.

Guidance on machine/trolley sizing and OEM/contractor compliance.

Digitally managing campaign & performance metrics using our proprietary business intelligence platform, Advanced Rail Insights by Global Rail Group.

Digitally managing campaign & performance metrics using our proprietary business intelligence platform, Advanced Rail Insights by Global Rail Group.

Maximizing Returns on Your Investment

A managed rail maintenance approach allows railway network service providers transition from a corrective rail treatment to a preventative maintenance cycle. Investing in independent QA/QC services ensure: